Flour and hulling mill

De Koker, 1866

De Koker is the only remaining industrial mill in Wormer.

In the past, Wormer had many more of them. Many of these mills supplied the flour for the bakeries of the famous ships’ barges, which served as provisions for sailors on whale hunting trips.

In 1928 the mill was closed down. After years of decay, De Koker was bought by the Zaansche Molen Association in 1944 and thoroughly restored. A second restoration followed in 1988, after which the interior was completed.

1. Groats and flour

From the beginning, De Koker was primarily a flour mill, but in the nineteenth century a second function was added with the installation of a hulling stone for hulling barley and rice. Hulling barley produces gort. Gort, rich in calcium and potassium, was once the most important food for the people, but was replaced by the rise of the potato. In its heyday, the Zaan region had no fewer than 121 flour mills, each producing around four hundred tonnes of groats a year. These days are long gone, although some aficionados still swear by a portion of porridge diluted with buttermilk and a dash of syrup.

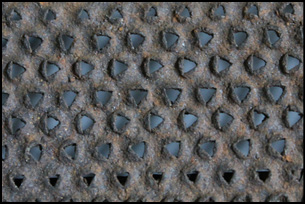

2. The heart of the mill is in the attic, where the actual shelling takes place. This takes place in a wooden vessel in which a stone, driven by a pivot, rotates along a wall covered with perforated sheet metal. The tin resembles the drum of a washing machine, with hundreds of holes punched into it. The sharp serrations of all these holes act as a grater to remove the husk from the barley grains.

3. The barley is poured into the narrow space between the husking stone and the and the tin. As the husking process creates a lot of dust, the tub can be closed with two crescent-shaped wooden lids.

4. The cold harp

To obtain high quality barley, it was often husked up to six times. The grains went ‘through the mill’, so to speak, six times.

An integral part of this process was sifting. The barley to be hulled flows down an inclined chute through a chute. The grains then end up in a series of sieves that are shaken back and forth by a connecting rod. In this way, debris such as small pieces of straw, branches, sand and dust are removed from the barley to be hulled. The unhulled barley grain is sifted on the so-called small or “cold” harp.

5. Flour milling

Unlike the hulling of barley, the milling of grain into flour requires two stones. These stones are stacked horizontally in a wooden container. The lower stone, the layer, does not rotate during the milling process. This stone is fixed. Only the upper stone (the runner) turns, driven by the stone spindle. Depending on the strength of the wind, the distance between the two stones can be increased or decreased.

6. The millstones have a pattern of grooves. These grooves were cut by the miller with a so-called butt hammer. The application of these grooves, a difficult and precise work, is called beating.

7. After grinding, the flour goes down the flour pipe to the lowest floor in sacks. Alternatively, the flour is collected in the bump (a different type of sieve from the harp), which allows white flour and bran to be separated.

8. All these operations require a lot of energy, which is provided by the wind. This mill is an capwinder. Only the cap with the sails is turned by the wind. There is a tail attached to the cap which can be turned by a winding wheel.

9. Inside the cap is a large cogwheel on the sails, surrounded by wooden brake shoes to stop the mill. This first gear drives a small gear attached to the central spindle beam. This spindle brings all the power down.

10. In the first attic you can see a large number of wooden gears. The central spindle, which is driven at the top of the cap and turns the millstones below, and a horizontal beam with a rope to lift the sacks of grain.

11. The wind is variable. In light winds the mill turns too slowly for production. The miller stops the mill and sets the sails on each sail to catch more wind and make the mill turn faster and more powerfully. In summer the sails are white, in winter the mill runs with brown sails.