Oil mill from 1693

Kalveringdijk, Zaanse Schans, Zaandam, NL

For more than three centuries, oil mills in the Zaanse Schans have been producing oil from various seeds.

Over the years, the equipment of these mills was improved until the peak of perfection was reached with the use of wind power. In the beginning, linseed and rapeseed were the raw materials used to produce oil. But the development of the steam engine led to the demise of most oil mills. The few survivors were forced to use the waste products of oil mills, such as cocoa husks, peanut shells and germs.

1. In this last oil mill, “De Bonte Hen”, linseed is used as raw material. The process begins under the large stones (each weighing 2,400 kg) where the material is crushed and ground. The resulting “flour” is then heated over a peat fire in a brick oven to encourage the separation of the oil.

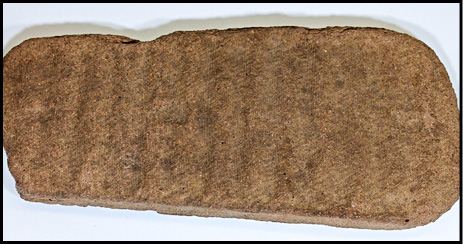

2. When this process is complete, the material slides from the fire into a pile of hanging woollen sacks. These woollen sacks, called “bulen”, are then placed in leather covers lined with a type of filter made of sisal.

3. These filters used to be made of horsehair. These “books” are placed in the press room on either side of thick iron plates.

4. The miller then starts the press. A heavy wooden pole weighing about 200 kg is lifted by the helmsmen in the shaft on the next floor and falls like a hammer on a wooden wedge in the centre of the press block. As the wedge is driven in, the blocks are pressed sideways against the pockets. After eighty strokes, the wedge develops a pressure of 280 atmospheres. The oil runs down and is collected in flat pans, after which the counter wedge is driven down to release the first wedge.

5. In the past, when oil was extracted from linseed and rapeseed, the whole process of pressing was repeated. The cakes were placed in a pestle and pounded into a mould. This was heated and pressed at an even higher pressure: 300 atmospheres.

6. Linseed oil was used in paints and varnishes and as a material in ‘linoleum’. Rapeseed oil was used for cooking, in the soap industry and in the past as a fuel for lamps.

7. The remaining hard and dry cake is taken out of the bag and can be sold as cattle feed. The oil is refined in oil mills and used in mayonnaise, salad oil, etc.‚

8. All these operations require a lot of energy, which is provided by the wind. Only the top part with the sails is turned by the wind. Attached to the moving top is a tail which can be operated by a paddle wheel on the gallery.‚

9. Inside the top is a large cogwheel on the sails-axle, surrounded by wooden brake shoes to stop the mill. This first cogwheel drives the small cogwheel of the main shaft. This shaft brings all the power down.

10. In the first attic you can see a large number of wooden gears. That’s where the main shaft drives the power at the wind to turn the stones below.

11. All the mills you see here on the bank of the Zaan river are maintained by the Zaansche Molen Society. Your visit to this mill helps us to preserve this industrial heritage. Don’t hesitate to visit another mill or the Mill Museum.

Thank you for your visit.